While order fulfilment is, by definition, the method by which a company processes a sales order to the customer’s specifications, that understates its importance. Customers hold more power than ever, are more informed and have higher expectations. Efficient order fulfilment is key to your brand’s reputation, your company’s profits and your ability to retain clients.

Without sales there is no business. Without order fulfilment, there are no sales.

What Is Order Fulfilment?

Order fulfilment is a process consisting of receiving and processing goods for distribution to customers.

What does order fulfilment mean?

Order fulfilment means fulfilling a sales order to the customer’s specifications. That is, delivering goods as promised at the time of sale. There are three main steps in this process: receiving, processing and shipping.

Why is order fulfilment important?

Companies make money by selling goods, products and services to businesses or direct to consumers. No matter whether you’re B2B or D2C, the sale is not complete until the sold items are received by that customer. Order fulfilment is how companies complete the sale and it’s at the heart of every business.

Order Fulfilment Process

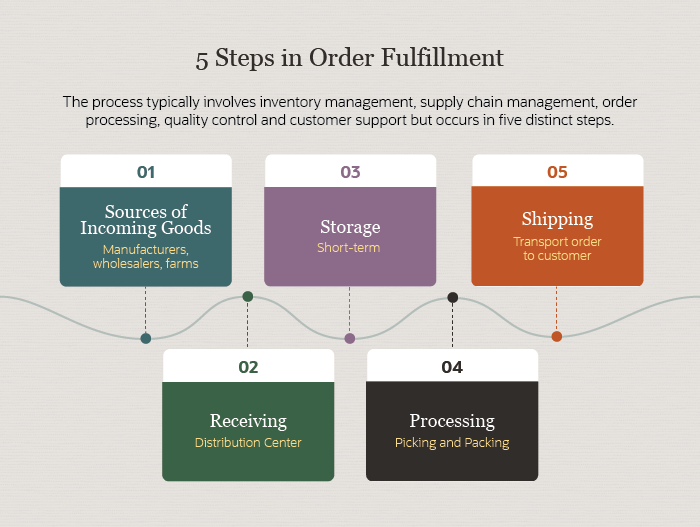

The order fulfilment process takes place in one or more distribution centres and typically involves inventory management, supply chain management, order processing, quality control and support for customers that need to report problems or make product exchanges or returns.

Receiving inventory

Goods may come from a third party, another company department or a company warehouse; a

pipeline (as with oil, fuel, water or some other fluid product); as digital data from a

database; or in a variety of forms from other external or internal sources.

In any

case, the incoming inventory must be counted, inspected and inventoried to ensure the proper

amount was received and the quality is acceptable. SKUs or bar codes on the arriving

products are used in the receiving and storage processes, and to retrieve goods from

internal storage later.

Inventory Storage

Once goods are received in the fulfilment centre, they are inventoried and either immediately disbursed or sent to short- or longer-term storage. Items are ideally stored just long enough to help organise the orderly distribution of goods for existing sales, rather than to hold product for future sales.

Order Processing

An order processing management system dictates the product picking and packing activities per each newly received customer order. In the online marketplace, order management software can be integrated with the shopping cart on an ecommerce website to automatically initiate order processing.

Picking

A picking team or automated warehouse robots select items from the warehouse according to a packing slip’s instructions. The packing slip contains specific information, such as a list of item SKUs, product colours, sizes, number of units and location in the distribution centre’s warehouse.

Packing

Packing materials are selected by a packing team or automated fulfilment robots to achieve

the lowest practical dimensional weight, which is calculated by multiplying package length

times width times height. Since space on delivery trucks is at a premium, optimising

dimensional weight (or DIM weight) is important to speed transport while also potentially

lowering shipment costs.

Further, packing teams often include return shipping

materials and labels in case the customer wishes to exchange or return the item for a refund

later.

Shipping

The order is sent to a transportation channel or shipping node to be shipped to the customer. Shippers and carriers—be they freight lines or airlines, FedEx, UPS or other carriers—determine freight billable costs by whichever is greater: actual package weight or its dimensional weight.

Even if the actual weight is low, such as with a t-shirt, packing it in the lowest DIM is often worth it to keep the packaging from adding significantly to the overall package weight. Also, most carriers have packaging rules to optimise their own profits from the shipping space they have available. Failing to meet those requirements can delay shipments if carriers refuse to accept the order.

Delivery

It is common for shipping routes to include more than one carrier. For example, FedEx may pick up a package at the fulfilment centre that will later be delivered by the USPS to the customer’s home. There are many reasons for these hybrid shipping methods. One common example is that the USPS delivers even to remote areas where most other commercial carriers do not. It’s simply more practical to use the USPS for the last mile of delivery in those cases.

Returns processing

Returns processing begins with including shipping materials and a return label with the original customer’s order. When a customer does return a product for exchange or a refund, the process must be executed carefully to ensure it’s appropriate to restock it. Obviously if the product malfunctions, it can’t be restocked. Nor can a soiled item. Returns processing involves quality control checks and sorting returned products accordingly. Return products are then restocked, returned to a vendor or manufacturer for a distributor refund or credit, or sent to a recycling centre.

Order Fulfilment Challenges

Order fulfilment challenges run the gamut from supply shortages and inventory management issues to failures in demand and logistics planning to kinks in the supply chain.

Inventory Management

Running out of stock leads to customer dissatisfaction, failures in the overall customer experience and harm to brand reputation. It is difficult for companies to repair the damage once it’s done. But there are exceptions: Customers tend to be more forgiving if shortages and delays are caused by a widespread weather event, a natural disaster or a Black Swan event(opens in a new tab).

Demand Planning

On the other hand, keeping too much stock on hand drives up storage and carrying costs. It also increases your risk since demand for those items may drop before you get them sold. It’s important to carefully predict and plan for demand levels in order to keep adequate supplies in stock without ever dipping too low or stocking too much of any given item.

Logistics Planning

Slow or missing deliveries, broken items and battered or wet packaging are all factors that can harm a company’s reputation and future sales, and in turn its profitability. It is essential then to carefully manage logistics so shipping doesn’t go awry and items aren’t damaged. Simply put, customer satisfaction is greatly affected by logistics, so keep a close eye on end-to-end—or warehouse to mailbox—performance.

Supply Chain Execution

Having a supply chain strategy entails evaluating cost versus benefit tradeoffs in terms of operational choices. For example, a company may choose a sole supplier for a given product to gain price breaks for the higher purchase volume. That’s also a good strategy to gain priority status with the vendor, which can make a difference in getting goods on time during periods of high demand. However, using a sole supplier model can backfire if anything goes wrong for that vendor—from employee strikes to natural disasters to their own supply shortages.

Supply chain execution (SCE) is the flow of tasks in the supply chain. Software applications are used to manage every activity within that chain. Specifically, material management, tracking the physical status and movement of the product, tracking data shares and data feeds, and managing financial information—particularly transactions among all parties.

SCE typically involves the use of multiple applications, such as order management, inventory management, warehouse management, transport management and logistics software.

Order Fulfilment Best Practices

Remember that the efficiencies to be gained in order fulfilment depend on great organisation. Best practices boil down to organise, organise, organise.

Start with the basics. Streamline your receiving processes so incoming shipments are processed quickly and damaged goods returned swiftly to the manufacturer for replacement. This will go a long way in preventing back-orders or long wait times for your customers.

Organise your warehouse for more efficient picking times. Place hot-ticket items upfront and close to human or robot pickers and packers. Place other items in your warehouse according to demand, with items least in demand being at the very back.

Organise shipping and logistics so you get the fastest possible delivery times to customers at the least cost. But also plan a shipping backup strategy in case something goes wrong, or carriers unexpectedly raise rates too high for your margins.

Automate as much as you can to save labour costs, improve working conditions, and make operations safer.

How Do You Choose an Order Fulfilment Strategy?

Choose an order fulfilment strategy according to the skills and resources available in your company. If fulfilment and logistic skills and resources are scarce, you may be better off outsourcing order fulfilment. If you have the means in-house, you can gain more control over operations and costs by doing it internally. If your company’s inhouse talent and resources are somewhere in the middle, you may want to opt for a hybrid model to give you some of the benefits of both worlds.

Order Fulfilment Models

Order fulfilment models have been refined over many decades, but the basics hold true, and that is for very sound business reasons.

What are the types of order fulfilment?

There are four order fulfilment models to choose from: in-house, outsourcing, drop shipping and hybrid. Each model fills specific business needs.

- In-house: The in-house model simply means that all steps in order fulfilment are performed internally.

- Third-party: This model entails outsourcing all order fulfilment activities to an order fulfilment vendor or other third-party.

- Drop shipping: The order is produced and shipped by the manufacturer. On the pro side, this lowers the barrier to entry and minimises overhead costs, key for startups and ecommerce companies. It also eliminates the middleman, which can potentially save the buyer money. On the cons side, it can also strip control from merchants, particularly in terms of inventory management and order fulfilment. It can also greatly delay shipments to customers, since many manufactures are in other countries, far from the merchant’s customer base. In that case, shipping may take more time and cost more or a distribution centre is set up and items ship from there.

- Hybrid: A hybrid model simply means a combination of two or more of the three models above. For example, a company may choose to handle order fulfilment of all or just popular products internally, but also choose to outsource fulfilment during peak periods, such as the holidays, and drop ship big and bulky items directly from the manufacturer.

#1 Cloud ERP

Software

Free Product Tour(opens in

a new tab)

Order Fulfilment FAQs

What does it mean when an order is in fulfilment?

This generally means that the order is somewhere in the fulfilment process but not yet shipped.

What is order fulfilment rate?

The order fulfilment rate is an efficiency measurement calculated by dividing the number of orders already processed by the total number of orders. It is also called the order fill rate.

|

Order Fulfilment Rate = Total number of orders process / Total number of orders |

What is the order fulfilment process?

The order fulfilment process typically involves receiving goods, short-term storage in a warehouse in the distribution centre, customer order processing (picking and packaging) and shipping and logistics.

What are the seven steps in the order fulfilment process?

The seven steps are receiving inventory, storage, order picking, order packing, shipping, delivery and returns.

What does order fulfilled mean?

An order is fulfilled when the customer receives it.

How do I start an order fulfilment business?

You’ll need a solid business plan mapping out all the important details, from facility and technology costs and location plans to business prospects, sales projections and the estimated capital you’ll need to get started and stay afloat. Outline your objectives and make detailed plans for receiving, storage, order processing and shipping strategies. Implement your plan and make adjustments as necessary to refine and streamline your business to optimise your profits and constantly improve customer satisfaction.