Learn everything you need to know about tracking inventory with cycle counting, including the methods, process, frequency, steps, and benefits.

What Is Cycle Counting?

Cycle counting is a method of checks and balances by which companies confirm physical inventory counts match their inventory records. This method involves performing a regular count and recording the adjustment of specific products. Over time, they have counted all their goods.

Warehouse managers and supply chain professionals often prepare the plan for staff to audit inventory. The most efficient inventory management plans lead to minimal transaction error rates and extremely high stock record accuracy without taking away from staff's essential tasks.

Regardless of whether a company uses periodic or perpetual inventory practices to track their inventory, regular cycle counting is a necessary auditing process to manage inventory counts.

Video: What Is Cycle Counting?

What Does Inventory Cycle Count Mean?

Regardless of whether a company uses periodic or perpetual inventory practices to track their inventory, regular cycle counting is a necessary auditing process.

Bill Conway, NetSuite Practice Director, Blue Horseshoe Solutions, describes the process in inventory management procedures:

Tweet“Many companies perform regular physical inventory counts as part of their yearly financial accounting practices. Large companies with thousands of items typically halt operations for up to a week or more to perform a full physical inventory count. Cycle counting is an inventory management option that allows you to count items in a designated area of the warehouse without stopping operations to perform a complete physical inventory.”

What Is Inventory Accuracy in Cycle Counting

When used as a metric, inventory accuracy is either a count or a cost. Determine inventory record accuracy (IRA) by using the inventory cycle count accuracy formula.

IRA = Matched inventory / # items counted

The goal of cycle counting is to identify and rectify any inventory record discrepancies. As with any process, it is helpful to understand your performance, if it is improving, and how you perform compared to industry benchmarks. A common KPI for this is the IRA number. You can adapt this formula for either the number of units or a dollar total. For dollars/units, use the formula:

IRA = [ 1-the sum of the absolute variance / # the sum of the total inventory ] x 100

For example, if a physical count was 354 and the system count was 375, calculate the IRA as:

= [ [1-(21/375) x 100%

=

94.4%

A result of greater than 90% may seem reasonable, but the goal is to achieve almost 100% accuracy.

Physical Inventory vs. Cycle Counting

A physical inventory counts all stock one time a year. Cycle counting counts small, preselected sections of inventory multiple times a year, sometimes as often as daily.

Performing only a physical inventory is a good choice for companies with minimal inventory. If you can easily count your stock without closing and inconveniencing clients, schedule and perform an annual inventory. For more information on conducting physical inventories, read NetSuite Best Practices: Annual Physical Inventory Counts.

Tweet“If you are not performing your cycle counts correctly or they keep indicating inventory discrepancies, perform a full physical inventory to determine your actual inventory position,” Conway advises. “If your company does not have a robust cycle counting policy or procedure in place, you should perform a full physical inventory audit as part of an ERP implementation plan. This practice helps ensure you are starting with quality data.”

Adding cycle counting to an annual physical count may be a good process for those who have a grasp on their inventory. The method also saves time while helping you improve current inventory management systems and helps businesses schedule and deliver product reliably.

How to Do Cycle Counting

You can perform cycle counting by scheduling high frequency, regular counts of sections, or bays as part of everyday operations. Use inventory cycle counting methods to do counts daily and assign specific workers for particular areas.

When developing a cycle counting program, first consider three main inputs:

- Number of SKUs:

Determine how many products, or stock-keeping units, you want to count at a time. Base what you choose to count on your overall number of SKUs, the number of high-value products and what is reasonable to count in intervals. - Available Counting Resources:

This resource is dependant on the number of available employees and how much time they can dedicate to counting stock. For example, some companies suggest employees use the time before shift end to count SKUs in their assigned areas. This timing takes advantage of the natural lull in employee productivity with relatively easy work. These employees should not have a stake in the accuracy of the numbers. - Counting Frequency:

How often you count inventory depends on how many SKUs you want to cycle count in the year. For example, if you wish to count 1,000 SKUs per year, count ~83 per month, ~21 per week, and ~3 per day, assuming you are only counting each SKU once annually. You may want to count high-value items more often. Either way, you must determine how long counters will take to record their SKUs daily.

Inventory Cycle Count Policy

An inventory cycle counting policy specifies when to perform counts periodically to confirm the inventory balances. Companies should also determine whether they will count products randomly or in a set pattern and whether they will have occasional “special” audits.

Inventory Cycle Counting Process

Companies start inventory cycle counting to eliminate the root causes of errors. This action leads to reliable control processes. After completing a full physical inventory to correct any stock discrepancies, the company institutes a regular counting program for maintenance.

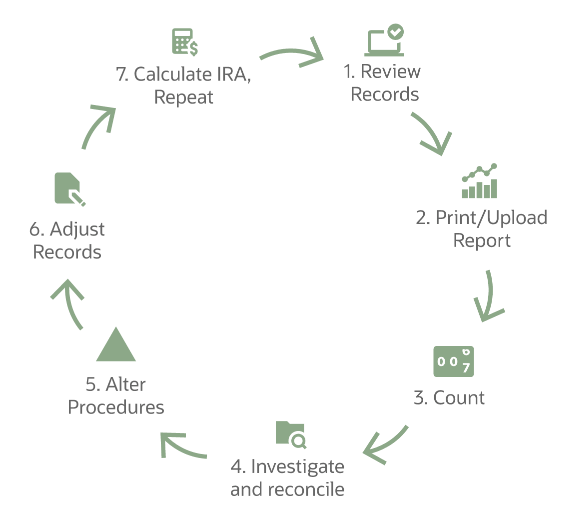

The steps to take during a cycle count are:

- Review Records

You want to start with an accurate database. Begin the process by reviewing and correcting the data entry on all the inventory transactions. - Print or Upload a Cycle Count Report

Create a cycle count report. If you are using a mobile device to do the count, upload the report to it. - Begin the Count

Counters should review the inventory locations, descriptions, and quantities from the report and compare it to what is physically on the shelf. - Investigate and Reconcile

Identify any differences found during the count and reconcile them with the stock manager. Look for patterns of errors. - Alter Procedures

Implement any inventory counting policies or procedures, if necessary. - Adjust Records

Make changes in the inventory record database to reflect what is on the shelf. - Calculate and Repeat

Audit inventory regularly and calculate the inventory accuracy percentage.

The Cycle of Cycle Counting

Methods of Cycle Counting

The main methods for cycle counting rely on either the physical area or sales ranking. For physical area counting, review high volume items more frequently. When using sales ranking methods, based on the Pareto Principle, count the faster-moving, more expensive items more often.

The Pareto Principle method, also called ABC cycle counting, assumes that 20% of the parts in a warehouse relate to 80% of the sales. These are the “A” items (“B” items account for 30% of the inventory and 15% of sales, and so forth). “A” items may be your fastest moving SKUs or most valuable assets. Inventory control software can identify the counted as A, B, or C items. You may want to count your “A” items more frequently, and “B” and “C” less and less regularly, respectively.

You can base ABC cycle counting on other metrics such as transactions and production numbers. There are many metrics you can use to identify which items have a significant impact on your organisation’s overall inventory cost.

However, most software systems rely entirely or in-part on ABC cycle counting, irrespective of the metrics used to identify the As, Bs, and Cs. Other methods of cycle counting include:

- Cycle Counting by Usage Only:

This process counts items in inventory that you use the most. Each time staff removes or adds one of these items, it can initiate inventory variance. - Control Group:

The process usually focuses on a small group of items that are counted many times in a short period and reveals any errors in the count technique (which can then be corrected). - Opportunity-based:

A form of cycle counting based on opportunities, such as critical points of the inventory management process, such as when an item is ordered or put away. These can be exception-based cycle counts, such as when the stock goes below its predetermined threshold, or when short-picks occur. Short-picks are when a company ships an order with less than the quantity the customer ordered. - Random Sample:

Just like it sounds, you randomly select a certain number of items to count. You can perform the count daily to account for a large percentage of the items in the warehouse in a reasonable period. - Objective Counting by Surface Area:

Irrespective of stock value, you will parse the storage area into smaller audit areas. Based on the warehouse map, the auditor counts items only in their allotted physical space. - Hybrid:

Each organisation should develop its own best practices for cycle counting. They can base their hybrid approach on its warehouse map, or a combination of location, value and throughput. Most hybrid plans start with the Pareto frequency analysis, and then a company will adjust it based on its needs.

The Frequency of Cycle Counting Methods and When to Choose Each

How often you do a cycle count depends on your company’s goals and the method you choose to use.

The Frequency of Cycle Counting Methods

| Method | Frequency | When to Choose this Method |

|---|---|---|

| ABC Analysis (Pareto) | Count "A" items most frequently, followed by "B" items, and then count "C" items the least often. Assume that the number of counts will decrease over time as the inventory records get more accurate. You will still maintain the proportion of counts between A, B, and C items. | Start with the ABC method when you need a customisable program that gives extra attention to essential products. |

| Cycle Counting by Usage Only | Count the highest used items most often and then less frequently for the other items. | Use this method when you have adequate controls for high-value items and need more. |

| Control Group | Perform this count several times over a short period. | Use a control group when you want to find process errors. |

| Opportunity-based | Use to count items at crucial points in the inventory management process, such as after every ten transactions of a specific item. | Use to count items at crucial points in the inventory management process, such as after every ten transactions of a specific item. |

| Random Sample | Use to count items at crucial points in the inventory management process, such as after every ten transactions of a specific item. | Use this method when you stock many similar items. |

| Opportunity-based | Use to count items at crucial points in the inventory management process, such as after every ten transactions of a specific item. | Use this method as a different, time-saving way to check your process' accuracy. |

| Objective Counting by Surface Area | How often you count is based on company goals, but you should to it at least once per year for each area. | To ensure storage locations are accurate. It can also help you find any patterns of stock discrepancy based on site. |

| Hybrid | Counting frequency depends on which methods you set up. | Your company needs a more flexible method of counting. |

Inventory Cycle Counting Benefits

No matter how good its replenishment, tracking and management systems are, organisations must do regular checks of actual inventory levels for key items. Maintaining an accurate item count can help reduce required safety stock and lower overhead costs.

Because it doesn’t force companies to shut down operations and perform a full physical inventory count at once, cycle counting has become a popular inventory management strategy for companies across all industries. Other benefits include:

- Higher order fulfilment rates

- Better customer service levels

- More accurate inventory assessments

- Higher sales

- More time between physical counts

- Fewer errors

- Less inventory write-offs and obsolescent inventory

- A more efficient operation overall

- Possible elimination of annual counts

- Improvement of the closing process

- Decreased audit fees

- No employee overtime costs

- Detect thefts in a timelier manner

Cycle Counting Challenges and Risks

Even the most organised of companies can have problems with inventory cycle counting. It’s easy to introduce inventory errors when dealing with multiple locations, paperwork lags and outstanding transactions. You can introduce false variances if you do not update the count in real-time. Therefore, define your process, track your inventory accuracy and aspire to a high degree of accuracy.

How to Increase Accuracy in Cycle Counting

Inventory management professionals favor cycle counting to annual inventory counts for its time and cost savings. Improve accuracy by using a methodological approach that accounts for any unique business needs and human involvement.

Make sure teams do the work at a time that makes sense for the business. Some businesses prefer to count at the beginning of the day, citing fresh staff. Other organisations say the end of the day is better because it does not take away from the staff’s routine jobs. Some organisations use a warehouse management system to assign counting by station, so staff never have to leave their station to perform their counts. More ways to sharpen accuracy include:

- In the case of variance, recount the items at the line level.

- Coordinate the reordering, picking and putting away of items after counting them.

- During active counting, freeze any activity on the items and their locations.

- Randomly alternate the counting staff.

Inventory Cycle Counting Best Practices

Irrespective of your auditing inventory method, its performance should be systematic and part of regular business operations. Each organisation should also decide the interval for counting based on its stock’s specifics.

Cycle counting best practices include:

- Close all transactions for inventory items before the cycle count.

- If using the ABC method, classify items into the respective counting groups using specified, documented processes.

- Count all products for all SKUs listed.

- Decide what to count when. It makes sense to count items that are of a high-value or that move quickly through the warehouse weekly. Count all other stock quarterly. Conway suggests listing items by warehouse location to decide how much you’ll count each combination each quarter.

- Use the inventory accuracy formula to see changes over time.

- Identify the fastest moving items in the warehouse. Mark them as fastest to slowest to figure out how to classify items for future counts.

- Dedicate specific personnel to counting teams.

- Ensure teams count all products at least once quarterly.

- Use zero counts. “If warehouse processes cause an empty bin by a picking order, then a command is given to the warehouse worker to have them count the bin and confirm it is empty. This action quickly verifies that the bin is empty and will help the facility confirm that the count completion of the item warehouse location level was correct,” explains Conway.

- Initially, you may want to do counts twice to ensure that the numbers are correct. A supervisor can check the counts against the inventory in the system.

- Perform investigations when errors crop up.

- Document everything: the process, the changes and the results.

Automation in Cycle Counting

Using automation in your cycle counting process can improve the accuracy of your results. Automation also lowers labour costs, boosts worker productivity, provides trust in your stock levels and enables real-time visibility as your inventory changes.

Thanks to technology, the cycle counting process has become easier, less intrusive and requires even less manpower. By replacing Excel spreadsheets or other manual inventory control systems with inventory control software, companies can more efficiently track their stock—all while reducing human error and saving time, money and valuable man-hours.

- Use software to implement an inventory control system (part of warehouse management system)

- Devices include mobile computers, robot counters, and barcode scanners

- Software can select the number of items and locations to count at a specific time

See how 2Pure Ltd streamlined its inventory management, showing inventory details right down to the bin location, with NetSuite ERP.

How NetSuite Helps with Inventory Cycle Counting

NetSuite’s Inventory Count feature improves inventory tracking and provides increased control over key assets. With this feature, firms can categorise inventory based on the volume of transactions and/or value, and enter regular periodic counts of on-hand item quantities to maintain inventory accuracy.

With its standard functionality, NetSuite not only helps you gain better control of your inventory, but it also takes a step further by extending those activities to its warehouse management solution and mobile radio frequency (RF) devices. With the mobile app, users can scan bins and items, automatically recording the cycle counts without leaving the floor. This makes auditing inventory less intrusive to daily work and reduces manual errors due to incorrect keying and lag time.

By implementing a cycle counting strategy that’s supported by inventory management software, companies get more accurate inventory levels; automatic prompts for items that need to be counted; the ability to categorise items based on volumes or value; improved quality assurance; and higher customer satisfaction rates.

Learn more about cycle counting in our inventory management solution.